Filters

Self-clinching nuts

A self-clinching nut provides an easy-to-install load-bearing thread in sheets that are otherwise too thin to be tapped. Over time, the product range has grown with the evolving demands of the industry.

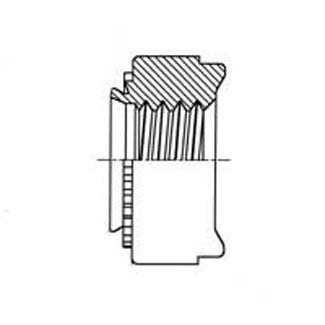

Self-clinching technology has revolutionized manufacturing fastening and made PEM® the global leader in the industry. When a self-clinching fastener (commonly referred to as a self-clinching nut or press nut) is pressed into a ductile material, it displaces the material around the mounting hole, causing it to cold flow into a specially designed annular recess in the shank or pilot of the fastener.

A knurled self-clinching ring, thread, ribs, or hexagonal head prevents the fastener from rotating in the host material once inserted - thus becoming a permanent part of the piece into which it is installed. The result is an innovative fastening solution that saves time, money, and is better for the environment.

Advantages of self-clinching nuts include greater thread strength, no welding splatter, can be incorporated into various materials, the panel and/or fastener can be pre-finished, no thermal stresses, reduced environmental concerns, lower energy consumption, improved fastener positioning, reduced installation cycle times, and can be incorporated into tooling.